Planning a playground or sports surface? EPDM granules are often recommended. But what are they, really? Understanding EPDM helps you choose wisely for safety and durability.

EPDM granules are durable, resilient rubber particles made from Ethylene Propylene Diene Monomer. They are prized for their weather resistance, vibrant colors, and safety features in sports and play surfaces.

As the CTO of MPU Coating, I often discuss various surfacing materials with clients like Mr. Zhang Wei. He’s always looking for high-quality, durable options for construction projects, including sports facilities, across Southeast Asia. EPDM granules consistently come up in these conversations, especially when we’re talking about running track materials or safe, attractive playground surfaces. Let’s dive into what makes these granules a popular choice.

What Does EPDM Stand For?

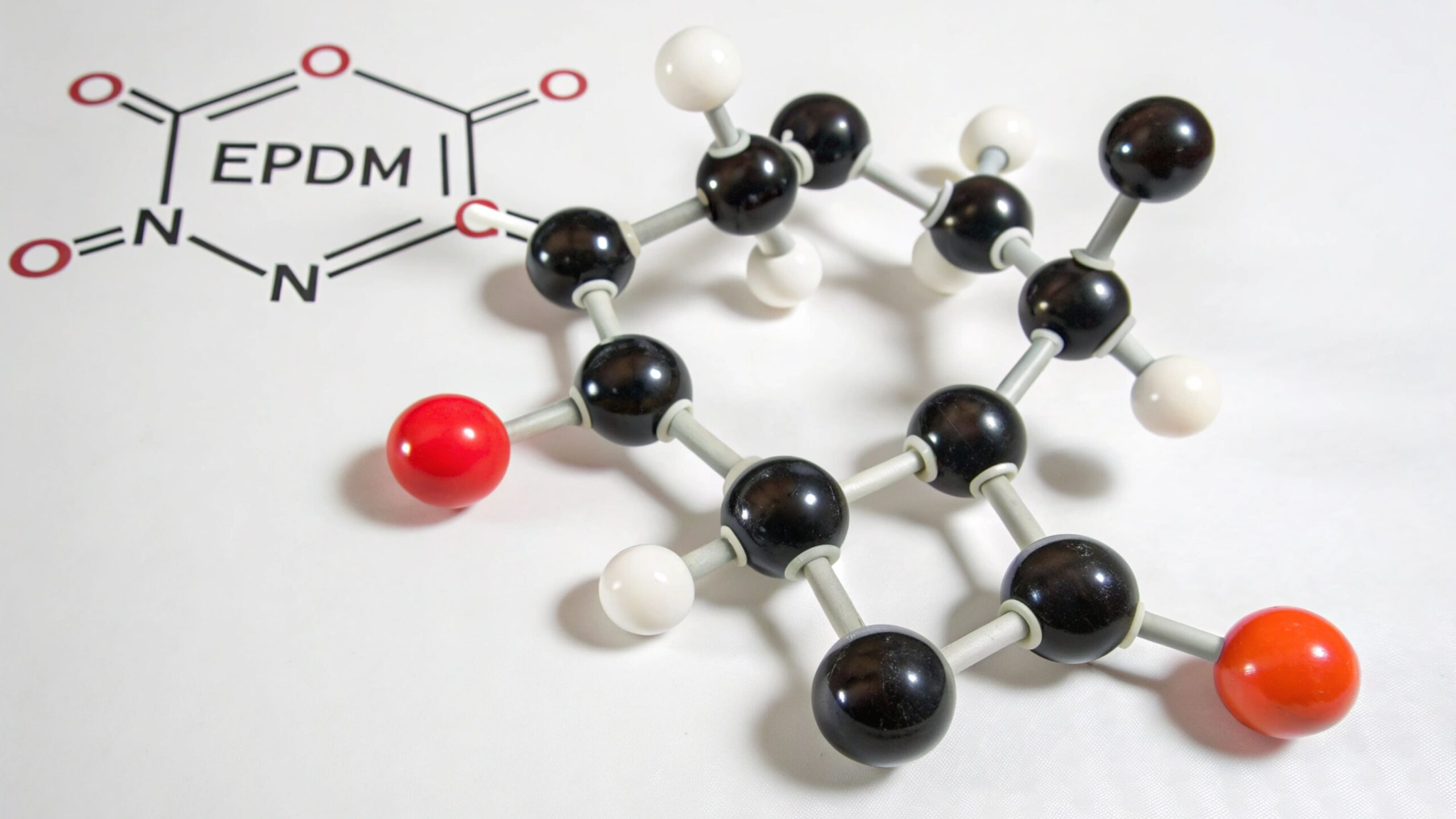

You hear "EPDM" a lot. But what do those letters actually mean? Understanding its chemical makeup helps explain why it’s so resilient for demanding applications.

EPDM stands for Ethylene Propylene Diene Monomer. It’s a synthetic rubber, a terpolymer made from ethylene, propylene, and a diene comonomer, which allows for sulfur vulcanization.

The name "EPDM1" might sound technical, and it is! It refers to the specific chemical building blocks that create this versatile rubber. Let’s break it down:

- Ethylene (E): This is one of the primary monomers. Ethylene contributes to the rubber’s good processing characteristics and its strength.

- Propylene (P): The second main monomer. Propylene helps provide the rubbery, elastic properties that EPDM1 is known for.

- Diene Monomer2 (DM): This is the crucial "third" monomer. Unlike the saturated ethylene and propylene backbone, the diene introduces unsaturated double bonds off the main polymer chain. These sites are essential because they allow the rubber to be cross-linked or "vulcanized" with sulfur. This vulcanization process3 transforms the raw, gummy polymer into the strong, elastic, and durable material we use in granules and other products. Common dienes used include Ethylidene Norbornene (ENB), Dicyclopentadiene (DCPD), or Vinyl Norbornene (VNB).

I remember when I first started in the coatings and materials industry, truly understanding these chemical distinctions was key. It explained why EPDM1 has such excellent resistance to weathering, ozone, and UV light compared to some other rubbers. The saturated backbone (from ethylene and propylene) is very stable, while the diene provides the "hook" for creating a robust, cross-linked network. This specific composition, first commercialized in the early 1960s, is what gives EPDM1 its signature durability and makes it a go-to material for outdoor applications where longevity is paramount.

| Component | Role in EPDM1 |

|---|---|

| Ethylene | Provides strength and good processing |

| Propylene | Contributes to elasticity and rubbery nature |

| Diene Monomer2 | Allows for sulfur vulcanization (cross-linking) |

What Substrate Is Best for EPDM?

Thinking of using EPDM? The surface underneath matters a lot. Choosing the right base ensures your EPDM installation performs well and lasts long.

EPDM granules are versatile but perform best on well-prepared, stable substrates like concrete or compacted asphalt for outdoor applications. For indoor uses, wood or specialized underlayments can also be suitable.

The success of an EPDM granule installation, whether it’s for a vibrant playground, a professional running track, or even a colorful decorative surface, heavily depends on the quality of the substrate beneath it. While EPDM itself is incredibly resilient, it needs a solid and stable foundation to perform optimally and achieve its expected lifespan. I’ve seen projects where corners were cut on substrate preparation, and the results were always disappointing down the line.

For most outdoor applications, the preferred substrates are:

- Concrete: A well-cured, properly sloped concrete slab provides an excellent, stable base. It needs to be clean, dry, and free from contaminants. Any cracks or imperfections should be repaired before applying the EPDM system.

- Asphalt: Compacted asphalt is another common and effective substrate, especially for larger areas like running tracks or driveways. Similar to concrete, it must be clean, well-compacted, and properly cured.

In some contexts, especially for indoor or more specialized uses, other substrates might be considered:

- Compacted Aggregate Base: For some playground applications, a well-compacted layer of crushed stone (often called a dynamic base) can be used, particularly if a "poured-in-place" EPDM system is being installed with a shock-absorbing SBR (Styrene Butadiene Rubber) base layer.

- Wood: For certain indoor decorative or safety surfacing, EPDM can be applied over a stable wood substrate, provided the wood is sound, level, and properly primed or sealed to prevent moisture issues.

- Existing Rubber Surfaces: In some retrofit scenarios, EPDM might be applied over an existing, sound rubber surface, but this requires careful evaluation of the old surface’s condition and compatibility.

The key characteristics of a good substrate for EPDM are stability, proper drainage (for outdoor use), and cleanliness. An unstable or uneven base will lead to premature wear, cracking of the EPDM surface, or delamination. At MPU Coating, we always emphasize thorough substrate assessment and preparation as a critical first step in any EPDM granule project. It’s an investment that pays off in the long-term performance and appearance of the final surface.

What Is the Binder for EPDM Granules?

Those colorful EPDM granules need something to hold them together. What’s the magic ingredient? The binder is key to creating a strong, flexible, and lasting surface.

The most common binder for EPDM granules is a polyurethane (PU) binder. This adhesive cures to create a strong, elastic matrix that holds the granules together and adheres them to the substrate.

When you see a seamless EPDM surface, like on a playground or a sports court, the granules themselves are only part of the system. The other crucial component is the binder that holds all those individual granules together and, in most cases, adheres the entire layer to the prepared substrate. For the vast majority of poured-in-place EPDM granule applications, the binder of choice is a polyurethane (PU) resin.

I’ve worked extensively with various polyurethane systems at MPU Coating, and their versatility is remarkable. For EPDM granules, specific types of PU binders are used:

- Moisture-Curing Polyurethane Binders: These are very common. They are single-component binders that react with moisture in the air and from the substrate to cure. They are relatively easy to use but require careful attention to ambient humidity and temperature.

- Two-Component Polyurethane Binders: These consist of a resin and a hardener that are mixed on-site just before application. They offer a more controlled and often faster cure, with less dependence on ambient conditions.

The polyurethane binder is mixed with the EPDM granules in precise ratios. This mixture is then troweled or poured onto the prepared substrate and leveled to the desired thickness. As the PU binder cures, it forms a strong, yet elastic, matrix that encapsulates the EPDM granules. This creates a durable, resilient, and seamless surface.

Key characteristics of a good PU binder for EPDM granules include:

- Strong Adhesion: It must bond well to both the EPDM granules and the substrate.

- UV Stability: Especially for outdoor applications, the binder should be UV stable to prevent yellowing or degradation over time. Aliphatic polyurethane binders are generally preferred for color stability.

- Elasticity: The binder needs to be flexible enough to accommodate movement and impacts without cracking, matching the inherent elasticity of the EPDM.

- Appropriate Cure Time: The cure profile should allow for sufficient working time but also cure quickly enough for practical installation.

Sometimes, for specific applications or pre-fabricated EPDM tiles, other adhesive systems might be used during the manufacturing process, but for on-site, poured-in-place systems, polyurethane binders are the industry standard. We ensure our clients understand the importance of using a high-quality, compatible binder with their EPDM granules to achieve the best results.

Why Is EPDM So Expensive?

EPDM offers great benefits, but it often comes with a higher price tag. What makes it more costly? Understanding the factors behind its price helps in budgeting.

EPDM is expensive due to raw material costs (ethylene, propylene influenced by oil prices), complex manufacturing processes requiring high-tech control, and strong demand from industries like automotive and construction, sometimes outpacing supply.

It’s true that EPDM granules and EPDM-based systems often represent a higher upfront investment compared to some other surfacing materials. This price difference isn’t arbitrary; it’s rooted in several key factors related to its production and market dynamics. When clients like Mr. Zhang Wei are evaluating options, it’s important to explain the value proposition behind the cost.

Here are the main reasons for EPDM’s higher price point:

- Raw Material Costs: The primary feedstocks for EPDM are ethylene and propylene, which are petrochemical derivatives. Their prices are directly influenced by global crude oil prices. When oil prices are high, the cost of producing ethylene and propylene increases, which in turn raises the manufacturing cost of EPDM rubber. The diene monomer, though used in smaller quantities, is also a specialized chemical with its own cost implications.

- Complex Manufacturing Process: Producing EPDM rubber is not a simple process. It requires sophisticated polymerization technology and precise control over reaction conditions (temperature, pressure, catalyst systems) to achieve the desired polymer structure and properties. This high-tech manufacturing involves significant capital investment in plant and equipment, as well as ongoing operational costs.

- Quality and Performance: EPDM is engineered for high performance, particularly its excellent weather, ozone, and UV resistance, as well as its good temperature stability and elasticity. Achieving these consistent quality standards requires stringent quality control measures throughout the manufacturing process, adding to the cost. You’re paying for a material designed to last for many years, even in harsh outdoor conditions.

- Supply and Demand Dynamics: EPDM is a versatile material with high demand from various major industries, including automotive (for seals, hoses, weather-stripping), construction (for roofing membranes, waterproofing solutions like polyurea), electrical (for cable insulation), and of course, sports and recreational surfacing. If demand from these large sectors grows faster than production capacity can expand, it can lead to tighter supply and upward pressure on prices.

- Specialized Grades and Colors: Producing vibrant, color-stable EPDM granules requires high-quality pigments and careful formulation to ensure the color doesn’t fade quickly. Custom colors or specialized grades with specific properties (e.g., enhanced flame retardancy) can also command premium pricing.

- Logistics and Processing: While not unique to EPDM, the costs associated with processing the raw EPDM rubber into granules, packaging, and international shipping (as we are a global supplier excluding the USA) also contribute to the final price.

While the initial cost of EPDM might be higher, I always encourage looking at the lifecycle cost. Its durability and low maintenance requirements often mean that over the long term, EPDM can be a more cost-effective solution than cheaper alternatives that may need frequent repair or replacement. It’s an investment in longevity and performance.

Conclusion

EPDM granules offer excellent durability, safety, and vibrant aesthetics for many surfaces. Their cost reflects their quality raw materials and advanced manufacturing, ensuring long-lasting performance.

External Links

-

EPDM rubber is renowned for its durability and weather resistance. Learn more about its advantages for outdoor use by exploring this resource. ↩ ↩ ↩ ↩ ↩

-

Understanding the Diene Monomer’s role is crucial for grasping EPDM’s unique properties and applications. Explore this link for in-depth insights. ↩ ↩

-

The vulcanization process is key to transforming raw rubber into durable materials. Discover more about this essential process through the link. ↩