Choosing the Right Commercial Non-Slip Deck Coating

A bustling restaurant patio, a busy hotel pool deck, or an industrial loading bay—what do they all have in common? They are all commercial spaces where a simple slip and fall can turn into a significant liability. For property managers and business owners, safety is non-negotiable. A wet, worn, or poorly maintained deck surface is a costly accident waiting to happen. This is where a high-quality non-slip deck coating becomes not just a maintenance task, but a critical investment in safety, compliance, and your peace of mind.

Ignoring the condition of your high-traffic walking surfaces can lead to devastating consequences, including legal action, soaring insurance premiums, and damage to your brand’s reputation. The good news is that you can proactively mitigate these risks. By choosing the right commercial anti-slip paint, you can create a durable, safe, and visually appealing surface that stands up to heavy use and the elements. This guide will walk you through everything you need to know to select the perfect non-slip coating for your property, ensuring you boost both safety and durability for years to come.

The High Cost of a Slippery Slope: Why Non-Slip Coatings are Non-Negotiable

Every commercial property owner’s primary goal is to reduce slip and fall liability. According to the National Safety Council, falls are a leading cause of preventable injuries. For businesses, this translates directly into a significant financial risk. A single incident can result in thousands of dollars in medical bills, legal fees, and workers’ compensation claims. Investing in outdoor floor safety is one of the most effective preventative measures you can take.

Beyond Obvious Dangers

While rain and ice are clear culprits, they aren’t the only factors making a commercial deck dangerous. Consider these common scenarios:

- Spills and Splashes: A poolside deck is constantly wet, while a restaurant patio is prone to spilled drinks and food.

- High Foot Traffic: Constant use wears down surfaces, smoothing them out and reducing their natural grip. This is especially true for high-traffic floor coating areas like entryways and walkways.

- Morning Dew and Condensation: Even on a clear day, temperature changes can create a thin, nearly invisible layer of moisture that makes surfaces slick.

- Cleaning Residues: Improper cleaning methods or certain detergents can leave behind a slippery film.

A proper non-slip deck coating is engineered with a textured floor finish. This is achieved by incorporating aggregates—like sand, quartz, or aluminum oxide—into the paint. These particles create a high-friction surface that provides superior grip even when wet, dramatically reducing accident risk and forming the foundation of effective commercial property maintenance.

Decoding Your Options: Types of Commercial Non-Slip Coatings

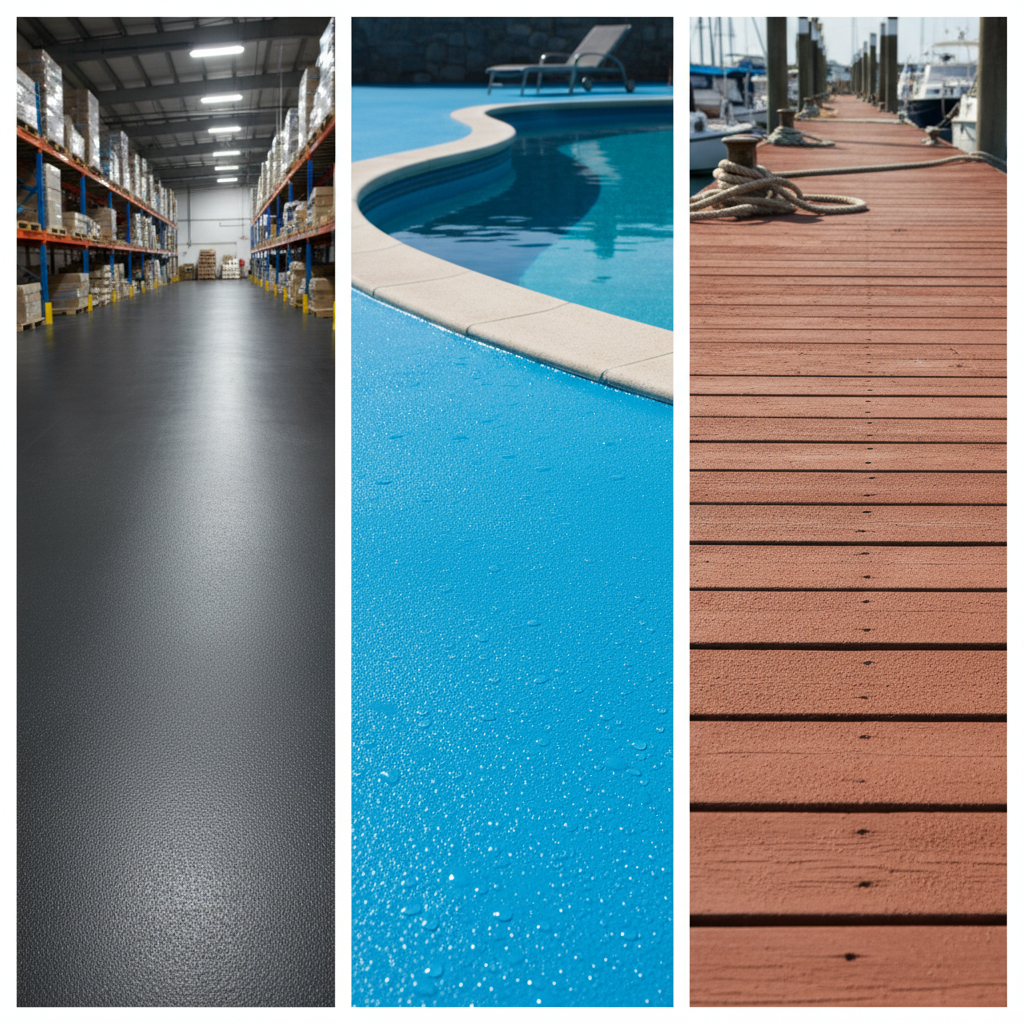

When you start your search for a non-slip coating, you’ll find a variety of chemical formulations, each with unique strengths. The three most common types for commercial applications are epoxy, polyurethane, and alkyd-based coatings. Understanding their differences is key to making an informed decision.

Epoxy Non-Skid Coating: The Heavy-Duty Champion

If you need the ultimate in durability and resilience, an epoxy non-skid coating is your answer. These two-part systems consist of a resin and a hardener that, when mixed, create a chemical reaction resulting in an extremely tough, rigid, and impact-resistant surface.

- Best For: Industrial facilities, warehouses, loading docks, commercial kitchens, and any area subject to heavy machinery, chemical spills, and constant abrasion. It’s the gold standard for industrial safety flooring.

- Pros:

- Exceptional Durability: Resists abrasion, impact, and heavy loads.

- Chemical Resistance: Stands up to oil, grease, solvents, and other harsh chemicals.

- Strong Adhesion: Bonds incredibly well to properly prepared concrete and metal surfaces.

- Cons:

- UV Sensitivity: Standard epoxies can yellow or chalk when exposed to direct sunlight over time. A UV-resistant topcoat is often necessary for outdoor applications.

- Rigidity: Can be brittle and may crack with significant substrate movement or temperature fluctuations.

Polyurethane Coatings: The Flexible, UV-Resistant Protector

Polyurethane coatings offer a fantastic balance of toughness and flexibility. While also highly durable, their main advantage over epoxy for outdoor applications is superior UV stability and elasticity.

- Best For: Outdoor decks, patios, pool decks, balconies, and pedestrian walkways exposed to direct sunlight. It’s an excellent choice for pool deck resurfacing.

- Pros:

- UV Stable: Resists yellowing and degradation from sunlight, maintaining its color and integrity.

- Flexibility: Can accommodate slight movements and temperature changes in the substrate without cracking.

- Abrasion Resistant: Offers excellent resistance to scuffs and scratches from foot traffic.

- Cons:

- Thinner Film: Typically applied in thinner coats than epoxy, so it may be less effective at hiding significant surface imperfections.

- Moisture Sensitive: The substrate must be completely dry during application.

A high-performance topcoat is an ideal solution for finishing outdoor deck systems, providing a long-lasting and color-stable durable deck finish.

Alkyd Coatings: The Tried-and-True Workhorse

Alkyd coatings are a more traditional, oil-based paint trusted for decades. They are known for their ease of application, excellent flow, and strong adhesion to a variety of surfaces.

- Best For: Wood decks, porches, boat docks, and general-purpose commercial areas with moderate foot traffic.

- Pros:

- User-Friendly: Easy to apply with a brush, roller, or sprayer.

- Cost-Effective: Generally more affordable than two-part epoxy or polyurethane systems.

- Good Adhesion: Penetrates and bonds well to wooden surfaces.

- Cons:

- Less Durable: Not as resistant to heavy abrasion or harsh chemicals as epoxy or polyurethane.

- Longer Dry Times: Can take longer to cure fully, especially in humid conditions.

The Blueprint for a Perfect Finish: How to Choose and Apply Your Coating

Selecting the right coating is only half the battle. To achieve a safe, long-lasting result, you must consider your specific environment and commit to proper application.

Step 1: Analyze Your Surface and Environment

The material of your deck and its environment are the most critical factors in your decision.

- Substrate: Is your deck wood, concrete, or metal? Each material requires a specific preparation process and a compatible primer.

- Location: Is the deck indoors or outdoors? If outdoors, is it covered or fully exposed to sun and rain? UV exposure is a major consideration.

- Specific Use: A poolside deck needs chemical resistance to chlorine, while a loading dock must withstand impacts from pallets and forklifts.

Step 2: Consider Foot Traffic and Durability Needs

Be realistic about the wear and tear your deck will endure. A quiet office balcony has vastly different needs than the main entrance of a retail center. For areas with constant pedestrian traffic or light vehicle use, investing in a premium epoxy or polyurethane system will pay dividends in longevity.

Step 3: Master the Art of Surface Preparation

This is the single most important step. A coating is only as good as the surface it’s applied to. Proper surface preparation for coatings ensures a strong bond and prevents premature peeling, chipping, and failure.

- Clean: Remove all dirt, oil, grease, and old, flaking paint.

- Repair: Fill any cracks, holes, or spalls in the surface.

- Profile: The surface needs a slightly rough texture for the coating to grip. This may involve acid etching or grinding for concrete, or sanding for wood.

- Prime: Apply a compatible primer to seal the substrate and promote topcoat adhesion.

Step 4: Ensure Compliance and Accessibility

For many commercial properties, meeting safety regulations is a legal requirement. This includes ensuring walking surfaces are compliant with the Americans with Disabilities Act (ADA). ADA compliant surfaces require a specific level of slip resistance. A professionally applied non-slip deck coating with a consistent textured floor finish can help you meet these standards and ensure safe access for everyone.

Your Final Coat: A Safer, More Durable Future

Choosing the right non-slip deck coating is a proactive step toward protecting your customers, employees, and your business. By moving beyond a simple coat of paint to a high-performance safety system, you transform a potential hazard into a durable, long-lasting asset.

Here’s a quick recap:

- Safety First: The primary goal is to reduce slip and fall liability and create a safe environment.

- Match the Coating to the Cause: Select the right coating type—epoxy for industrial toughness, polyurethane for UV resistance, or alkyd for general-purpose use.

- Preparation is Everything: A clean, dry, and properly profiled surface is the foundation of a durable deck finish.

- Think Long-Term: Investing in a higher quality system may cost more upfront but will save you significant money in maintenance, repairs, and potential legal fees.

Ready to take the next step in safeguarding your commercial property? Assess your deck’s condition, consider the traffic and environmental demands, and explore high-quality coating solutions tailored to your needs. Your business deserves a foundation as safe and reliable as the services you provide.