Choosing marine paint feels overwhelming. Wrong choices lead to costly failures. We simplify it, guiding you to the best protection for your ship.

The right marine paint depends on application area, budget, and desired durability. Alkyds are economical for general use, chlorinated rubber for water resistance, epoxies for toughness, and polyurethanes for premium topcoats.

Selecting the ideal marine maintenance paint can seem like navigating a complex chart. Each paint type – Alkyd, Chlorinated Rubber, Epoxy, and Polyurethane – offers unique advantages and is suited for different challenges your vessel faces. As CTO of MPU Coating, I’ve seen countless situations where the right paint choice made all the difference in longevity and cost-effectiveness. Mr. Zhang Wei, our distributor partner in Southeast Asia, often emphasizes the need for clear guidance for his clients. This helps them make informed decisions for their large construction and marine repair projects. Let’s dive into each to help you make the best pick.

When is Alkyd Paint the Most Economical Choice for Ship Maintenance?

Need basic protection without breaking the bank? Alkyd paints offer a cost-effective solution. But are they always the best value for your specific needs?

Alkyd paints are best for general-purpose applications above the waterline, like accommodation areas or some deck fittings, where cost is a primary driver and exposure isn’t overly aggressive.

Alkyd paints, based on alkyd resins, are often the first option considered when budget is tight. I’ve seen them used extensively on various vessels for areas not constantly exposed to harsh marine conditions. For instance, on a small coastal trader I once consulted for, they used alkyds for their interior cabins and non-critical deck equipment purely due to budget constraints, accepting the shorter maintenance cycle.

- Key Characteristics:

- Cost-Effectiveness: Their biggest selling point is the low price per liter. For large surface areas requiring basic protection, this can mean significant upfront savings.

- Ease of Application: They are generally single-component and forgiving, making them easy for crews to apply with minimal specialized equipment.

- Decent Aesthetics: They provide a reasonably glossy finish and good initial appearance.

- Limitations to Consider:

- Durability: Not as tough as epoxies or polyurethanes. They can become brittle and crack over time, especially with significant temperature fluctuations.

- Drying Time: They are relatively slow-drying, which can extend maintenance schedules. Below 5°C, they may not dry properly.

- Chemical Resistance: Poor resistance to strong chemicals and solvents. Not suitable for cargo holds carrying aggressive substances or areas prone to chemical spills.

- Immersion: Unsuitable for continuous water immersion, like ballast tanks or underwater hull areas.

At MPU Coating, while we offer a range of high-performance coatings, we understand the place for alkyds in a comprehensive maintenance strategy, particularly for less critical zones where frequent, low-cost touch-ups are acceptable.

Why Choose Chlorinated Rubber Paint for Your Vessel’s Protection?

Fighting constant moisture and rust? Chlorinated rubber paints are known for water resistance. But do their benefits outweigh their limitations for your ship?

Chlorinated rubber paints excel in providing good water and chemical resistance, especially for boot tops, topsides, and decks. They offer fast drying and good adhesion over various surfaces.

Chlorinated rubber paints have long been a staple in marine maintenance, particularly for their protective qualities against water. As a chemist, I appreciate their straightforward formulation and effective barrier properties. I remember a fishing fleet owner who swore by chlorinated rubber for his vessels’ boot tops because of its quick drying and reliable water barrier in that constantly splashed zone.

- Key Characteristics:

- Water Resistance: Their low permeability to water vapor and oxygen makes them excellent for areas frequently wetted or exposed to high humidity. This is a step up from basic alkyds.

- Fast Drying: This is a significant advantage, allowing for quicker recoating (often 4-6 hours at 20°C) and reduced downtime during maintenance periods.

- Good Adhesion: They typically adhere well to various substrates, including previously painted surfaces (with proper preparation). Their self-dissolving nature allows for good intercoat adhesion even after some time.

- Ease of Use: Often single-component, making them relatively easy to apply by brush, roller, or spray.

- Limitations to Consider:

- Temperature Sensitivity: They can degrade at higher temperatures (above 60-70°C), especially in humid conditions. This limits their use in engine rooms or on hot surfaces.

- Solvent Sensitivity: Not resistant to aromatic hydrocarbons and certain strong solvents. Contact with animal/vegetable oils and fats can cause softening.

- VOC Content: Traditional formulations can have higher VOC content, an increasing concern due to environmental regulations. We are always looking at lower VOC alternatives like some of our specialized polyurea coatings.

- Intercoatability: While they recoat well on themselves, applying other paint types like epoxies or alkyds directly over them can cause cracking or wrinkling.

For many general marine applications needing better-than-alkyd water resistance, chlorinated rubber remains a viable option, provided its temperature and solvent limitations are respected.

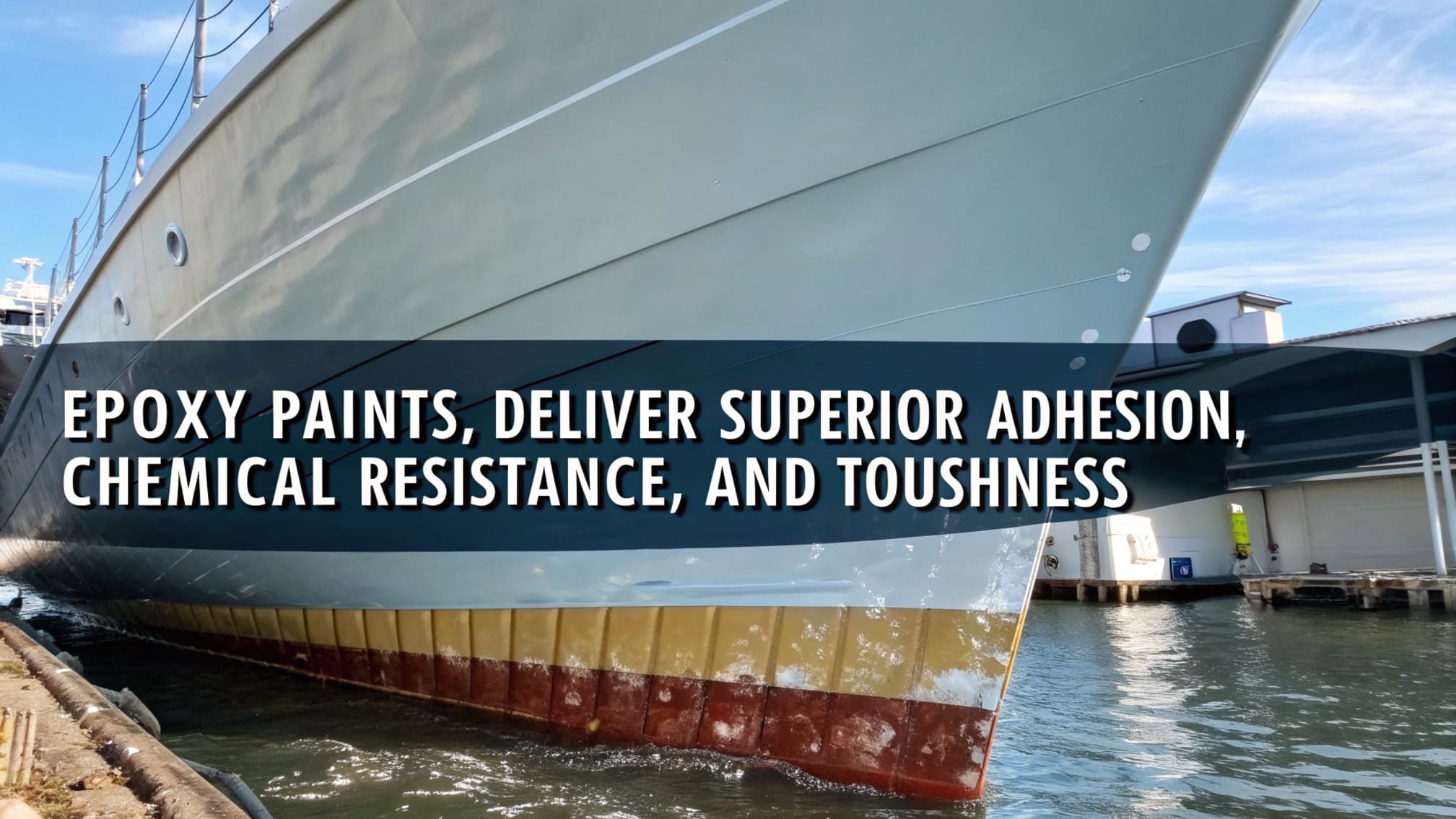

What Makes Epoxy Paints the Go-To for Tough Marine Environments?

Facing extreme corrosion and abrasion? Epoxy paints offer robust, long-lasting protection. But is their demanding application process always worth it for your vessel?

Epoxy paints deliver superior adhesion, chemical resistance, and toughness. They are ideal for high-wear areas, underwater hulls, ballast tanks, and as primers under high-performance topcoats like polyurethane.

When it comes to serious protection, epoxy paints are often the industry standard. At MPU Coating, our advanced formulations, including polyurea and high-solid epoxies, are built on the principles of toughness and adhesion that epoxies are known for. I’ve seen epoxies perform exceptionally in the harshest conditions, from the underwater hull of large tankers to lining cargo containers carrying abrasive materials.

- Key Characteristics:

- Superb Adhesion: They bond incredibly well to properly prepared steel, concrete, and other substrates. This is crucial for long-term performance.

- Excellent Corrosion and Chemical Resistance: They form a very hard, impermeable barrier that withstands seawater, chemicals, and abrasion. Ideal for industrial protective coatings.

- High Build: Can be applied in thicker coats (70-300µm or more per coat), providing substantial protection with fewer applications.

- Versatility: Can be formulated for various needs, including high solids/low VOC, or for specific uses like potable water tanks or as part of a color steel tile repair system.

- Limitations to Consider:

- Surface Preparation: They demand meticulous surface preparation, usually to Sa2.5 blast cleaning standard. Skipping this step leads to failure.

- UV Resistance: Most epoxies are prone to chalking and degradation under direct sunlight. They usually require a UV-resistant topcoat (like polyurethane) for exterior applications.

- Application Conditions: Often two-component, requiring precise mixing and attention to pot life. Curing can be slow in cold temperatures, though winter grades are available.

- Cost: Generally more expensive than alkyds or chlorinated rubber, both in material and application labor.

Despite the demanding application, for critical areas requiring maximum protection, the investment in a quality epoxy system, like those used in residential polyurea floorings or swimming pool polyurea linings where durability is paramount, often pays off through extended service life and reduced repairs.

Is Polyurethane Paint the Ultimate Topcoat for Durability and Appearance?

Want a ship that shines and withstands the elements? Polyurethane topcoats promise gloss and toughness. But are they the right final layer for every situation?

Polyurethane paints offer excellent gloss retention, UV resistance, and durability. They are premium topcoats for superstructures, topsides, and decks, providing a long-lasting, attractive finish over suitable primers like epoxies.

Polyurethane (PU) paints, particularly two-component aliphatic PUs, represent the pinnacle of topcoat technology for many marine applications. As a manufacturer, we see huge demand for their combination of aesthetics and performance. Think of them as the armor that also looks good. I recall a yacht owner who insisted on a specific high-gloss polyurethane finish; years later, his vessel still looked new despite constant sun and sea exposure.

- Key Characteristics:

- Excellent Gloss and Color Retention: They maintain their appearance for a long time, even under harsh UV exposure. This is why they’re favored for visible areas like superstructures and hull topsides.

- Superb Durability and Abrasion Resistance: They form a very tough, hard-wearing film that resists scratches, impacts, and general wear and tear.

- Chemical Resistance: Good resistance to a wide range of chemicals, oils, and weathering.

- Flexibility: Can be formulated for varying degrees of flexibility, important for structures that experience movement. Our polyaspartic coatings, a type of advanced polyurea with polyurethane-like properties, also offer this benefit for applications like colored pavement.

- Limitations to Consider:

- Cost: Polyurethanes are among the more expensive paint types.

- Application Sensitivity: Typically two-component, requiring careful mixing and application. They can be sensitive to moisture during cure, potentially leading to bubbling or "blooming." Application usually requires temperatures above 0°C and humidity below 85%.

- Primer Requirement: Best used as a topcoat over a suitable primer system (often epoxy) for optimal adhesion and corrosion protection. They are not usually direct-to-metal for aggressive environments.

- VOCs: Some formulations can have higher VOCs, though lower VOC options are increasingly available.

For shipowners who want the best possible long-term appearance and protection for their vessel’s exterior, a polyurethane topcoat over a robust epoxy primer system is often the recommended solution. It’s an investment in quality that truly lasts.

How Do Environmental Factors and Application Realities Influence Your Marine Paint Choice?

Beyond paint type, conditions matter. Harsh weather and application limits can ruin a perfect plan. How do you match paint to real-world ship life?

Tropical humidity, extreme temperatures, available surface preparation methods, and recoat windows heavily influence paint selection. Choosing a system compatible with your operational realities ensures success and avoids premature failure.

Choosing the right paint chemistry is only half the battle. As I often discuss with clients like Mr. Zhang Wei, who operates in Southeast Asia’s challenging tropical climate, the environment and practical application constraints are critical. A paint that performs well in a controlled shipyard might fail quickly if misapplied or unsuited to the operational environment. I’ve seen perfect paint specifications lead to disappointment because the application crew couldn’t achieve the required surface prep at sea.

- Key Environmental & Application Considerations:

- Temperature & Humidity:

- Low Temperatures: Can significantly slow curing for many paints (especially epoxies and alkyds; alkyds often won’t dry below 5°C). Some paints (e.g., certain epoxies) have "wintergrade" versions for use down to -10°C. MPU Coating’s products often feature rapid curing, even at low temperatures.

- High Humidity (>85%): Can affect cure, cause blushing (especially with polyurethanes), and trap moisture under the film. This is a major concern in tropical regions.

- Surface Preparation Capabilities:

- Ideal (Sa2.5): If you can achieve this high standard of blast cleaning, epoxies and high-performance systems like polyurea paint are viable.

- Limited (St2/St3): If only power or hand tool cleaning is possible, you might be restricted to more surface-tolerant primers or specific alkyd/chlorinated rubber systems.

- Recoat Windows & Downtime:

- Fast-curing paints like some polyureas or chlorinated rubbers are advantageous if downtime is minimal. Long recoat intervals for other paints (e.g., alkyds 8-15h, epoxies 3-6h+) need to be factored into the maintenance schedule.

- VOC Regulations: Increasingly stringent regulations may dictate the use of high-solids, low-VOC, or waterborne coatings.

- Expected Service Life & Budget:

- A short-term fix might warrant a cheaper alkyd. For long-term protection (e.g., >15-20 years for a polyurea roof waterproofing coating), a robust epoxy/polyurethane or polyurea system is more economical over its lifespan.

- Temperature & Humidity:

Making the right choice involves a holistic assessment:

| Factor | Impact on Alkyd | Impact on Chlor. Rubber | Impact on Epoxy | Impact on Polyurethane |

|---|---|---|---|---|

| Low Temp Cure | Very slow, may not cure (<5°C) | Slower, generally above 0°C | Slow, may need special grade | Slower, generally above 0°C |

| High Humidity | Can delay drying | Risk of poor cure/adhesion | Can trap moisture if surface damp | Risk of blushing/bubbling |

| Surface Prep Need | Less demanding (St2/St3 ok) | Moderate (St3 preferred) | High (Sa2.5 ideal) | High (over good primer) |

| UV Resistance | Fair, chalks over time | Fair to good | Poor (chalks without topcoat) | Excellent |

Understanding these interplays ensures you select a paint system that not only has the right chemical properties but can also be successfully applied and perform reliably in your specific operational context. This is key for solutions like industrial floor coatings or coatings for specialized areas like hospital polyurea applications where environment and use-case are paramount.

Conclusion

Choosing the right marine paint—Alkyd, Chlorinated Rubber, Epoxy, or Polyurethane—depends on your specific needs. Balance cost, performance, and application realities for optimal vessel protection.